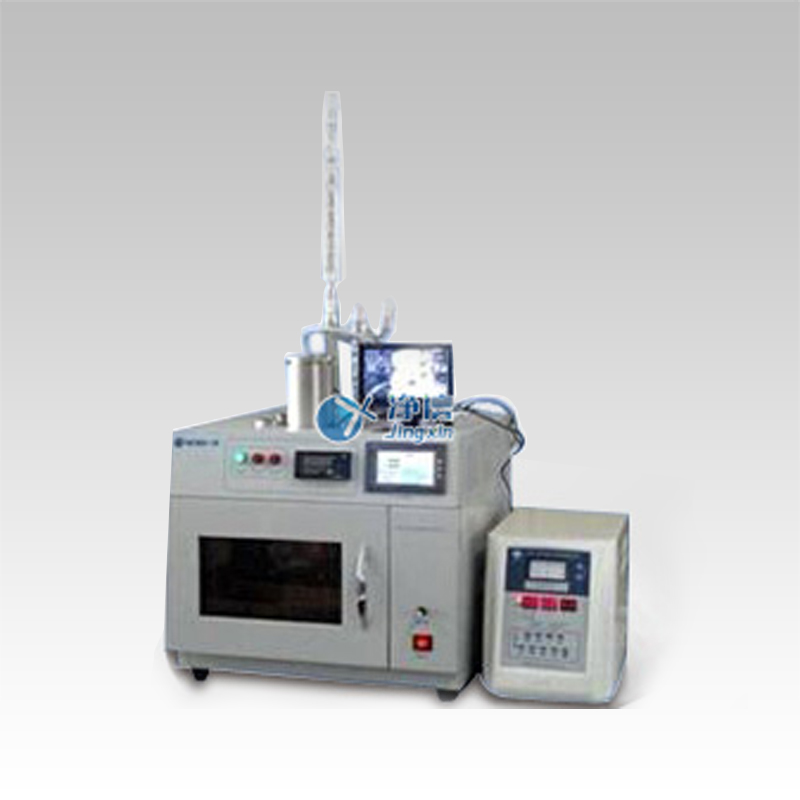

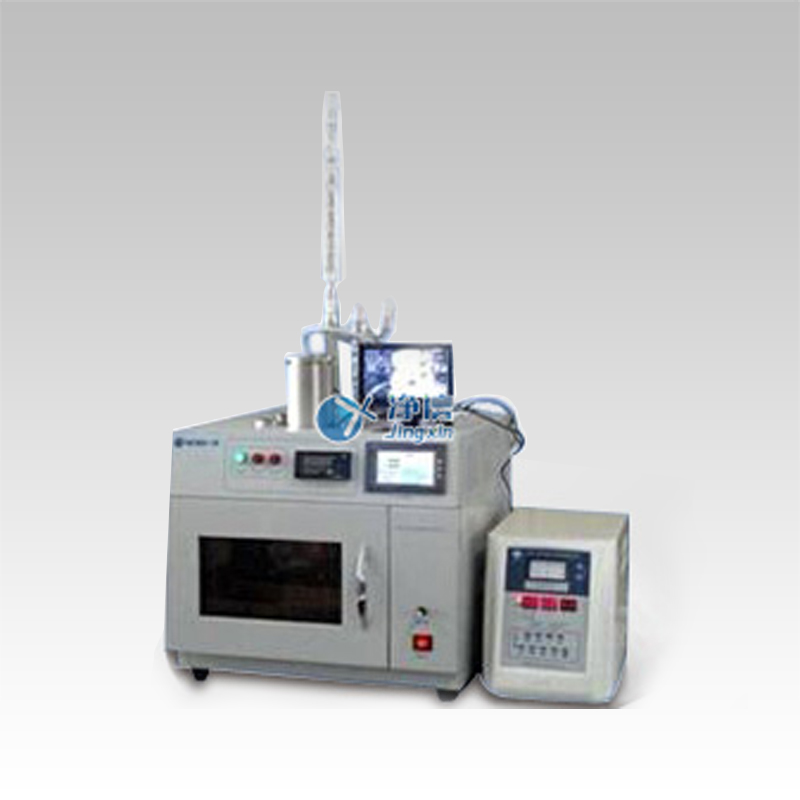

Model:JX-1A

Brand:Jingxin

Specifications :Set

Introduction:It is widely used in factories, research institutes, colleges and universities, medical, chemical, physical and chemical testing departments for chemical experiments, material analysis and processing, and microwave extraction, ......

Features:

1. Automatic constant microwave power mode

The user only needs to freely set the microwave power required for the experiment on the touch screen, the microcomputer will automatically control the microwave power at the point set by the user, and the system will automatically deal with the temperature drift of the device and the change in magnetic flux, as well as the external power supply and other related factors. The resulting power change.

Advantages: It is convenient to realize the experiment of power repeatability.

2. Temperature control feedback power automatic control mode

The temperature in the experiment is given priority, and the microwave power change is controlled by an automatic control algorithm to keep the experiment process to a stable temperature.

Advantages: Suitable for related experiments where samples have requirements for temperature rise.

3. Multi-section heating mode

Divide the entire experimental process into several experimental sections, and set different parameters for each stage of the sample reaction.

Advantages: suitable for the experimental process of complex reaction samples

Application range:

It is widely used in factories, research institutes, colleges, medical, chemical, physical and chemical testing departments for chemical experiments, material analysis and processing, and microwave extraction, synthesis, digestion, catalysis, and heating of materials.

technical parameter:

Main parameters | Parameter range |

Microwave power: | * 0~700W non-pulse continuous linear adjustable, microwave power can be set arbitrarily on the touch screen, advanced fuzzy algorithm is used to dynamically change (stabilize) the power density in the cavity in real time |

Microwave frequency: | * 2450MHz±50MHz, ultrasonic power and frequency: 650W/25KHz, ultrasonic transducer is immersion type, ultrasonic power is continuously adjustable; ultraviolet wavelength: 365nm, power: 250W |

* Full Chinese true color touch screen man-machine interface, industrial-grade microcomputer as the central control processor, | |

* The microwave power is automatically feedback controlled according to the set temperature control temperature, and the temperature curve is displayed in real time | |

* Microwave power non-pulse continuous linear adjustable and variable pulse dual-mode control | |

* The microwave output can work either in non-pulse continuous adjustable working mode or variable pulse control mode. The pulse period and pulse time can be set by the user. The pulse mode control can ensure the instantaneous electric field intensity in the cavity under the microwave state. The non-pulse continuous mode means that the electric field intensity in the cavity changes linearly in real time, and the variable pulse state is the optimization of the above two states. | |

* A variety of reaction mode options, the program executes segmented work in segmented multi-zone reaction mode: 10 segments of operating parameters can be set | |

* The high-precision contact platinum temperature sensor monitors and controls the reaction temperature in real time, displays the current temperature and the set temperature control temperature, and automatically controls the temperature. | |

* Temperature measurement range 0~300℃, temperature measurement accuracy: ±0.2℃ temperature control accuracy: ±1℃ | |

* The Chinese interface prompts the status of the work process, and the user can edit, store, and modify various reaction control parameters, and call the reaction plan | |

* The cavity has built-in magnetic stirring, the stirring speed is continuously adjustable, and a mechanical stirring device can be installed on the top | |

* The instrument has a built-in camera and is equipped with a TFT color liquid crystal display, which can observe the reaction of the material in the cavity at any time | |

* The instrument is equipped with a standard video output interface, and the user can select a video capture card when necessary, and record the reaction process in dynamic or static digital images on the computer | |

* There are multiple experimental vessel insertion channels on the top (a total of three channels with end caps, which can be closed when not in use), and microwave choke is performed on each channel, which is safe and reliable. When the channel is completely open, there is no microwave leakage. The top channel It is mostly used for condensing reflux, water passing, aeration, adding mechanical stirring, etc. | |

* Stainless steel cavity, corrosion-resistant and high-temperature resistant, the cavity uses a large volume, with a magnetic stirring function, the stirring speed is continuously adjustable, and can be used alone or in combination with other functions; | |

* Multiple safety interlocking protection devices such as magnetron temperature protection, door switch protection, etc., standard RS-485 computer communication interface, and support MODBUS communication protocol (users can choose special control acquisition software to upload field data to remote computers download | |

* The microwave leakage of the whole machine is better than the standard, safe and reliable. Reaction volume: 0.2~500mL; | |

* More functions can be customized according to user requirements. Microwave leakage is better than the standard, safe and reliable. | |